What are thermal labels?

There are two different types of thermal labels commonly used, which are direct thermal labels and thermal transfer labels. These labels generate imagery, text, or barcodes by utilising heat, which activates the process. As they use a different process from normal labels, they do not require ink or, in some cases, even a ribbon, making them a practical choice. Due to their efficiency and versatility, thermal labels have become increasingly popular across various industries. The thermal transfer label market is expected to grow to $4.93 billion by 2029 at a compound annual growth rate (CAGR) of 9.6% (The Business Research Company), highlighting the rising demand for reliable and cost-effective labelling solutions in businesses worldwide.

Direct Thermal Labels and Thermal Transfer Labels

Direct thermal labels: Direct thermal materials feature a chemical layer applied to a paper or synthetic base, activated by heat. When processed through a direct thermal printer, the printer’s elements heat up, activating portions of the chemical layer to generate the desired image. These materials enable the printing of variable information on both blank and pre-printed labels.

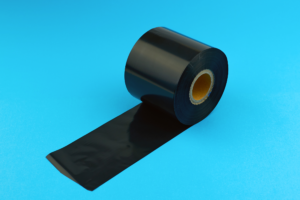

Thermal transfer labels: The printing process involves a thermal transfer printer, where a ribbon layer is positioned over the label at the print head. The heated print head elements transfer ink from the ribbon onto the label, forming the desired image.

Selecting the ideal thermal label for your requirements

It’s important to consider both the intended purpose and your specific needs when choosing a thermal label. For short-term labelling needs, direct thermal labels are a great choice if you’re looking for something affordable. They work perfectly for things like event badges, mailing labels, and invoices.

If your labels must withstand harsh situations, thermal transfer labels are the ideal option. They are beneficial for asset tracking, industrial labelling, and product labelling due to their durability and resistance to environmental changes. By carefully assessing the lifespan, environment, and labelling requirements, you can select the thermal label that best suits your needs.

Direct thermal labels have numerous advantages.

Several benefits make direct thermal labels a popular choice for specific labelling applications.

Low cost solutions: Direct thermal labels are great since they are easy to use and reasonably priced. These labels are less expensive to produce and need no ink or ribbon unlike normal labels, which simplifies the printing process. They are therefore an excellent choice for companies looking for a low-cost labelling solution.

Printing that is both speedy and effective: The lack of ink or ribbons results in a reduced number of components to oversee, ultimately resulting in faster printing speeds. This efficiency proves especially advantageous in environments that require large-scale printing, where time is an invaluable resource.

Maintenance Made Easy: By eliminating the need for ink or ribbon replacement, the maintenance requirements are significantly reduced. This, in turn, leads to fewer instances of downtime and interruptions when it comes to replacing consumables.

Clear and Precise: Thermal labels produce high-resolution prints with sharp text and vivid details, ensuring readability. Using heat to print makes sure the pictures look clear. These labels can be used in many ways, making them perfect for lots of tasks.

Saving Space: Adding small heat printers to work areas is made easy by eliminating the need for ink and ribbon holders. This streamlined design not only saves space but also enhances the overall setup.

Environmentally Friendly: Thermal labels that don’t use ink or ribbons to throw away make less trash than other ways of printing. They are a thoughtful choice for helping the environment.

Short-Term Applications: Direct heat labels are good for uses with a short life span, like sending packages, papers from buying things and tickets to events. They are great when lasting a long time is not the main issue.

Ideal for Variable Data: Thermal labels that can be used straight away are good for situations needing changing information, like barcodes or list numbers. This is because they work well and get things done accurately.

Rapid Deployment: Simple thermal printing gives fast label making without much setup or changes. This is good for quick labelling needs when you need them right away.

Limitation: Shorter Lifespan: Direct thermal labels are not designed for long-term use, especially when exposed to light, friction or heat. They are also more sensitive to environmental conditions such as heat, UV light and moisture, whereas thermal transfer labels are much more durable.

The benefits of transfer thermal labels

Durability and Longevity: Thermal transfer labels are strong and tough, able to handle tough conditions. They can handle water, chemical substances and exposure to UV light without being damaged. That makes them perfect for uses where labels need long-lasting looks.

High-Quality Printing: Thermal transfer stickers make clear prints with sharp, detailed words and pictures. They are very good quality. Using ribbons helps to get the ink onto labels correctly. This makes them look great and can be used for branding things or telling what they are.

Versatility in Label Material: Thermal transfer printing can be done on many types of label materials like paper, polyester, and polypropylene. This versatility enables customisation to match specific application needs.

Colour Printing Options: Thermal transfer labels offer the flexibility to print in various colours using colour ribbons. This is particularly advantageous for labels that require visual distinction or enhanced branding.

Consistent Print Quality: Thermal transfer printing uses a process that makes sure all labels have the same quality. This reduces differences and keeps them looking good.

Suitability for Harsh Environments: Heat transfer stickers are great for things that face difficult situations, like signs outside or labels in factories. They’re also good when you track things and put them on products kept somewhere tough.

Barcode and Data Matrix Quality: The good printing skills of thermal transfer labels make them great for barcodes, QR codes and data matrix codes. This means you can count on precise reading without any issues.

Reduced Risk of Fading: Using strong ribbons and heat transfer methods greatly lessens the chance of colours fading over time. This makes sure that information printed on labels stays good for as long as is wanted or needed.

Label Customisation: Thermal labels that move heat can be changed around so you have choices like putting in different data each time, such as special numbers or end dates.

Limitation: Not Ideal for Short-Term Use: Thermal transfer labels are designed to be durable, which means they are not that necessary for short-term use. Direct thermal labels would be more cost-effective for short-term use.

Conclusion

To sum it up, thermal labels are a flexible and quick way to meet different labelling needs. They are of two basic types—direct thermal and thermal transfer. They use heat to make pictures and words on labels without needing ink cartridges or sometimes ribbons, saving money while making things quicker. Direct thermal labels are fast and cheap, good for short-term labelling like shipping labels.

Thermal transfer labels, which use heated print heads and ink ribbons to work well in tough conditions. They are strong and can last for a long time because of this feature. Picking between them is based on what you need, showing how thermal labelling can help different uses easily and well.

Are you in need of effective thermal labels? Here at Labels Zoo, we are experts in the label printing industry, with years of experience and a dedicated team committed to delivering high-quality solutions. We provide thermal labels in all shapes and sizes, ensuring you get the perfect fit for your needs. Contact us today to find out more.

01/01/2026

What Makes Thermal Printing Different

From shipping operations to stock control, clear labelling is what keeps products moving efficiently through a business. It ensures items are stored in the right place, picked accurately, packed correctly and delivered to the right destination. In many ways, labels are the quiet organisers of every supply chain, essential to…

Christmas is the season of thoughtful gifting, homemade treats, beautifully wrapped parcels andfestive organisation. Often, it’s the smallest details that make the biggest difference, and labels, specifically Christmas Labels, are one of them. More than just a practical tag, a well-designed Christmas label addspersonality, professionalism and a touch of magic,…

Printing labels at home or in an office environment can initially seem like a complicated endeavour, particularly if you have never undertaken such a project before. However, with careful planning, the right materials, and a clear understanding of the process, it is entirely achievable to produce professional-quality results using standard…