Thermal label printers use heat to create to an image. Two main types of thermal printing techniques exist, direct thermal and thermal transfer.

Direct Thermal

The label surface is coated with a heat-reactive layer which turns black when in contact with the heat from the print head. This heat-reactive surface will effectively cause the print to fade when exposed to sunlight, strong artificial light or friction (cartons rubbing together in transit for instance) with the speed of fading dependent upon the intensity of the light or friction. For this reason, direct thermal labels tend to be used for short-shelf-life products such as fresh food. Although there are no ribbon costs associated with these labels, there are other cost implications as without the ribbon acting as a protective insulator between the print head and the label, the print head will wear more quickly requiring more frequent replacement.

Direct thermal synthetics are a good choice for carton and retail pack labelling in the chilled and frozen food sectors where the labels are exposed to high levels of moisture and rough handling during transportation

Advantages of Direct Thermal Labels:

- Simple to use; a ribbon is not required as it images directly onto the label: This simplicity reduces operational complexity and costs associated with ribbon replacements.

- Used in most printers: These labels have technology that is widely compatible with various types of printers, making them versatile for different applications.

- Cost-effective: Eliminating the need for ribbons reduces consumable costs, making these labels economical for businesses.

- Greater productivity due to no ribbon changeovers: Workflow interruptions are minimised without ribbon changes, enhancing overall productivity.

- Clear and consistent images for good readability and ‘scannability’: Direct thermal labels produce high-quality prints suitable for easy scanning and readability.

- Suitable for both 1D and 2D barcodes: They can effectively print a range of barcode types, supporting diverse barcode application needs.

- Paper and synthetic material options available: These labels are adaptable to different environmental conditions and durability requirements.

- The quality, stability and durability of the image are suitable for most common requirements: These labels provide dependable image quality and durability suitable for many standard labelling needs.

Disadvantages of Direct Thermal Labels:

- Can fade over time (6-12 months): The prints on direct labels may fade over several months, which can affect their readability and longevity.

- Overexposure to heat or UV light discolours the material, making the print harder to read: These labels are sensitive to heat and UV light, which can cause the material to darken or yellow, impacting the clarity of the print.

- Limited abrasion resistance: They are more susceptible to damage from rubbing or abrasion compared to thermal transfer labels, which can affect their durability in high-contact environments.

Thermal Transfer

The labels are printed through a thermal transfer printer where, at the point of the print head, a layer of ribbon is placed on top of the label. The print head elements heat up and cause the carbon pigment that is on the ribbon to transfer to the label, creating the required image.

Thermal transfer paper labels are a good choice where direct thermal is not suitable or the print quality of the ribbon is preferred.

Thermal transfer synthetic labels are more durable so are better suited for long-life applications such as outdoor labelling, or applications where high levels of moisture or scuffing are expected.

Advantages of Thermal Transfer Labels:

- Excellent print definition for text, images and barcodes: They provide high-resolution prints, ensuring clarity and precision for detailed text, graphics, and barcodes.

- Ideal for small characters and line work: The technology for these labels excels in printing small fonts and intricate line work, making it suitable for applications requiring fine details.

- Suitable for both 1D and 2D barcodes: They support a wide range of barcode types, ensuring compatibility with various industry standards and requirements.

- Wide variety of paper and synthetic materials available including clear, pearl, metallic, and fluorescent: These labels come in diverse materials to meet specific aesthetic and functional needs, enhancing design flexibility.

- Coloured ribbons available for branding and promotional uses: These labels can be customised with coloured ribbons, enabling branding and promotional messaging.

- Better resistance to heat, moisture and chemicals: They offer enhanced durability and are capable of withstanding harsh environmental conditions, including exposure to heat, moisture, and chemicals.

- Stable and durable images that are long-lasting: Theser labels produce prints that are stable over time, ensuring longevity and readability throughout their lifecycle.

- Higher-speed printing: They enable faster printing speeds compared to direct thermal labels, enhancing efficiency in high-volume printing environments.

- Longer printhead life: Thermal transfer technology typically extends the life of printheads, reducing maintenance costs and downtime associated with printhead replacements.

Disadvantages of Thermal Transfer Labels:

- Not all printers are thermal transfer compatible: Compatibility issues can arise as not all printers support thermal transfer technology, limiting options for printer selection.

- Ribbons must be kept in stock are an additional cost; a ribbon saver can reduce the amount of ribbon used: Maintaining an inventory of ribbons adds to operational costs, and while ribbon savers can help reduce consumption, they require additional investment.

- Requires additional setup time and ribbon changeovers: Compared to direct thermal printing, thermal transfer printing requires more setup time for loading ribbons and occasional changeovers during operations, which can interrupt workflow.

- Ribbons can wrinkle and compromise print quality: If not handled properly, ribbons can wrinkle during printing, affecting print quality and potentially causing errors or reprints.

Label Construction

All four components of the label are important in their own right, however, the face stock, tends to require the most immediate consideration as it is the surface on which you are actually printing. Does the label need a topcoat or protective coating? This topcoat is used to protect the print job from various types of environmental conditions. There are two main types of coating:

Varnish – This is what you would use when you want to have a protective gloss applied to the face stock.

Laminate –This type of topcoat is generally used when a label will come into contact with chemicals or if the label needs to be protected against abrasion.

Another major component is the type of material on which you will need to print to complete the job. There are various types of materials and films from which to choose; choosing the correct one is what will separate a successful printing job from an unsuccessful one. Let’s take a look at the most commonly used types of face stock:

Paper is the type of label most typically used. It is made from natural wood or pulp.

Film is generally made from a synthetic or plastic material. For the most part, these types of labels can be utilised for decals, beverage identification or whenever moisture resistance is needed.

Foil is made from aluminium or alloys and is great when needing to label a rigid or semi-squeezable container.

Static Cling labels are vinyl face stocks that are used for most smooth surfaces such as glass, and painted metal.

Magnets are made with paper or film on the uppermost layer with a bendable magnet as the bottom layer.

Holograms are micro embossed metallic film, that is intended to be more eye-catching

So which type of Thermal Label should I use?

Given the advantages and disadvantages of both types of thermal label, your primary consideration should be the type of application for which the label is intended. Here’s a quick guide to help you to select the appropriate thermal label for your print job:

Introducing or Direct Thermal Labels

- Box Quantity – 12 rolls per box

- Label size: 4” x 6”

- Perforation every label

- 475 per roll on 25mm cores

One of the newest additions to the zoo, the Badger LZ101 is our Direct Thermal Eco Perm paper label with general purpose permanent adhesive.

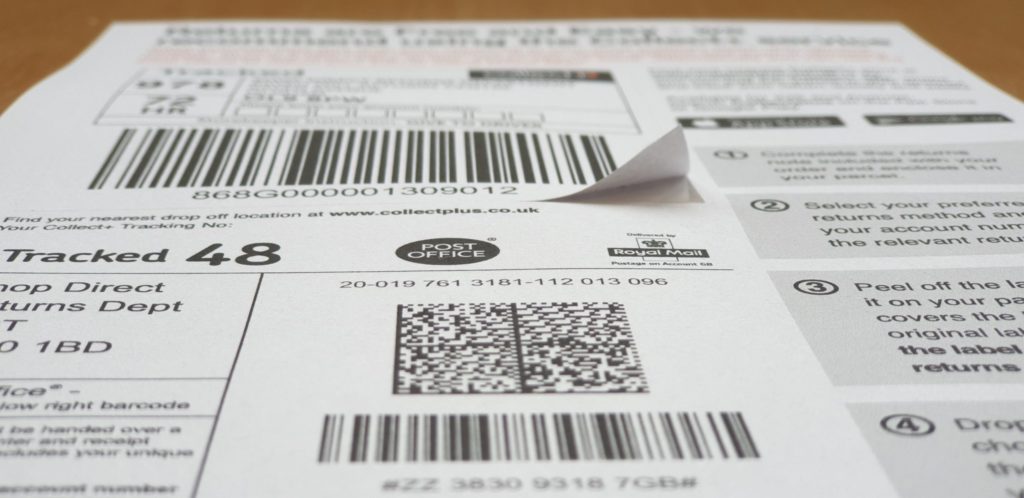

Suitable for Zebra printers as well as a variety of other printers, these versatile and cost-effective labels are useful for easily printing addresses, shipping labels, and 2D barcodes for Royal Mail. A favourite of online retailers and couriers, these thermal labels will stick reliably to various packaging surfaces, including cardboard boxes, to ensure your important information stays intact.

Still Unsure? Let us help

At Labels Zoo, we produce labels for a wide variety of clients across multiple industries. Our Zoo Keepers are market-leading experts when it comes to all things labels. Whether you need more information about thermal labels or would like to discuss any of the products in our extensive range, we’re here to help.

Call us on 0800 707 6567 or send us a message